Renamed

to “Funplay Systems” and Started Playground

Equipment

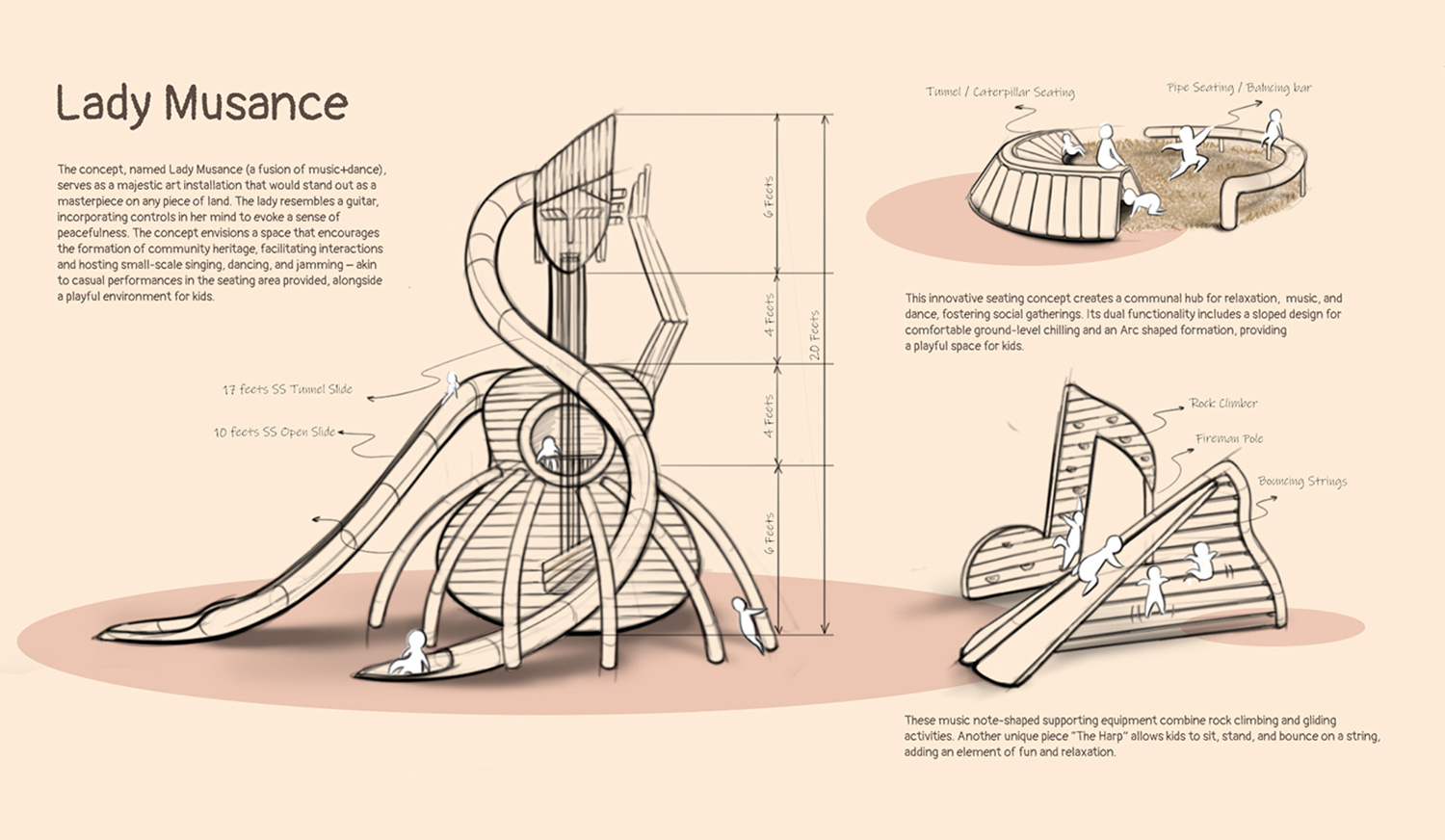

By 2005, he received his first order to fully manufacture a

plastic playground slide. Without a sales team, he single-handedly managed

every aspect. The years 2005 to 2010 marked Fun Mould's entry into

playground systems, investing in new designs and products.

After establishing itself in playground spare parts, Fun Mould Engineers set

its sights on manufacturing full playground systems. They aggressively

expanded their offerings from 2005 to 2010 with new slides, railings,

canopies and more.

As the company grew, so did the team. In 2005, with over 6 staff members and

50 workers, Fun Mould changed its name to Funplay Systems. By then, plastic

had become dominant in the industry.

First Installed Multi-Play Product